Blast Effects

The door is designed for blast pressure on door surface up to 28 bar (2,8 MPa; 406 psi); up to 9 bar blast overpressure is tested with prototype door BT1-2424 at German Army Test Laboratory WTD 52 (certificate-no: WTD52GF210-04/2018-Z); blast pressure up to 28 bar (406 psi) is calculated by FEM Analysis.

Overpressure direction

The overpressure wave direction is tested direct to the front.

Product Data

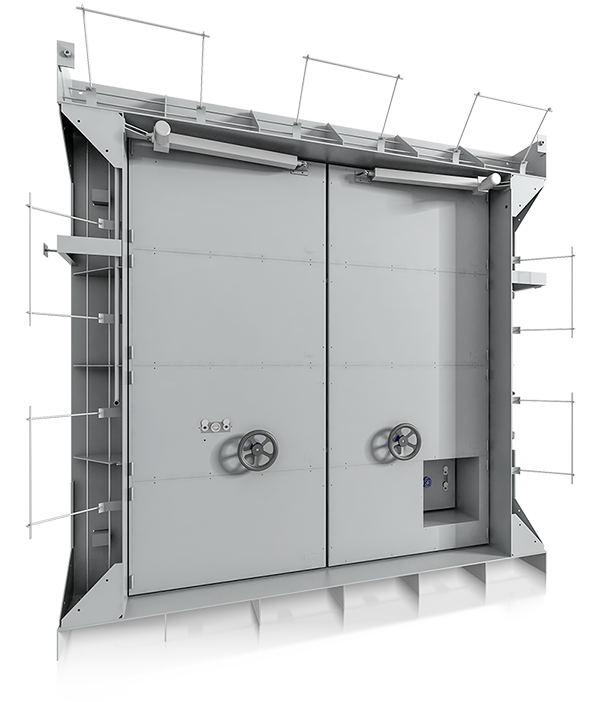

Blast resistant door in a high efficient construction of steel and reinforced concrete.

The mounting combines surface mounting and in wall mounting; sided hinged; swinging type; the door can be operated from inside and outside, manual operation of the door for opening and closing;

door thickness: 500 mm

concrete slab thickness: 300 mm

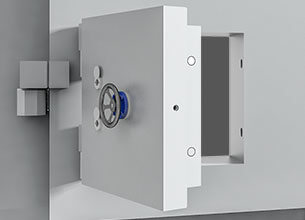

with 3 side bolt work and wheel handle – inside and outside; opening from inside as well as outside

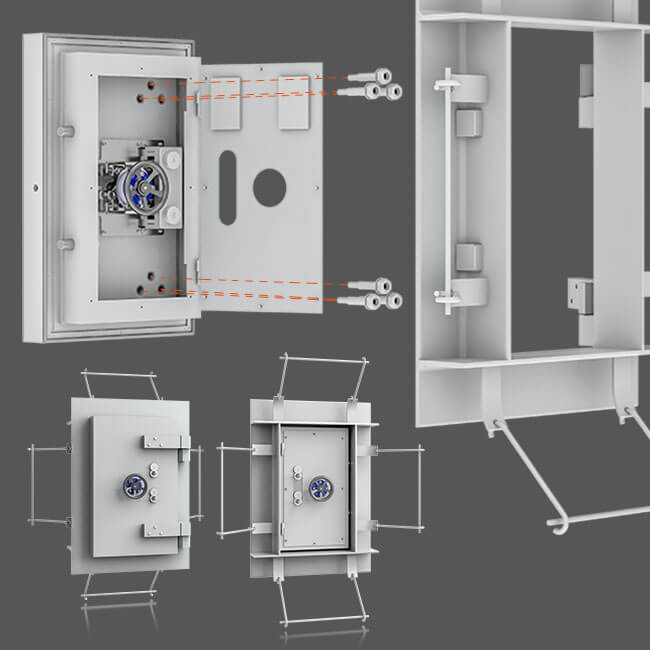

Description of latching

Door locked with round pin (dia 80 mm) and central bolt work, locking 50 mm; each leaf is hinged with 2 strong hinges in vault style, which allows door opening 180°, hinge pins are machined and polished from 80 mm diameter steel, rotating in sinter bushing.

Blast door operation

Force required to set the door in motion from the 90-degree open position app. 120 N, optional opening from inside and outside by electronic, lifting cylinder is available.

Door frame

The heavy steel frame is constructed from 500 mm by 500 mm L-shaped angle and prepared with anchoring studs.

Gasket seals are provided as recommended for reinforced concrete doors; the seals are typically used for reinforced concrete doors to improve the weather seal and provide door silencer; sealed doors have full door perimeter and all door penetrations sealed; perimeter seals are rubber gasket type; gaskets are removable, capable of sealing the mating surfaces and resistant to the atmospheric environment; the gaskets cushion the impact of the door against the frame so that steel to steel contact is not made during closing.

Door finish: door painted with primer resisting corrosion

Static material strength: steel plate according;

- EN 10025-2/2004,

- EN 10029 A/N

- EN 10163-2 A/1

- AD-2000 W1

- quality: S235JR+M

- minimum static yield strength 300 N/mm² (Mpa)

- maximum static yield strength 412 N/mm² (Mpa)

- minimum tensile strength 410 N/mm² (Mpa)

- minimum tensile strength 566 N/mm² (Mpa)

- elongation at rupture: 27% - 37%

- concrete C45/55:

- minimum static yield strength 60 N/mm² (Mpa)

- break load min.: 1500 kN test acc. DIN EN 12390

Dynamic analysis and deformation

Dynamic finite element analysis by calculation software LS-Dyna Version 970-3535 maximum deformation in door leaf = 2.1mm (BT3-3439, BT3-4545)) 100 % function of door (BT3-3439, BT3-4545) after blast with 5 bar.

Technical changes forbidden.

View the complete technical specifications

| Model art. no. |

Outer dimensions* height (mm)width (mm)

|

Clear opening height (mm)width (mm)

|

Weight with concrete (kg) |

Weight steel only (kg) |

Door thickness (mm) |

|---|---|---|---|---|---|

| BT3-2330 | |||||

| BT3-2330 | 30004000 |

23003000 |

9700 | 5500 | 500 |

| B3-2439 | |||||

| B3-2439 | 31004900 |

24003900 |

12650 | 7500 | 500 |

| BT3-3325 | |||||

| BT3-3325 | 40003500 |

33002500 |

11400 | 6600 | 500 |

| BT3-3942 | |||||

| BT3-3942 | 45005000 |

39004200 |

19700 | 12600 | 500 |

| BT3-4040 | |||||

| BT3-4040 | 46004800 |

40004000 |

19700 | 12400 | 500 |

| BT3-4045 | |||||

| BT3-4045 | 46505300 |

40004500 |

22000 | 13800 | 500 |

| BT3-4240 | |||||

| BT3-4240 | 50005000 |

42004000 |

22200 | 13100 | 500 |

| BT3-4250 | |||||

| BT3-4250 | 50006000 |

42005000 |

26800 | 16200 | 500 |

| BT3-4945 | |||||

| BT3-4945 | 56505500 |

49004500 |

26000 | 16800 | 500 |

| BT3-4950 | |||||

| BT3-4950 | 56506000 |

49005000 |

28500 | 18500 | 500 |

| BT3-6565 | |||||

| BT3-6565 | 72507500 |

65006500 |

47300 | 31350 | 500 |

* without protruding elements